It was a busy Tuesday morning in Brushy Creek when a local auto shop contacted our office with an urgent garage issue. Their main commercial garage door had become stuck halfway open, preventing vehicles from entering or exiting the workspace. Business had just begun for the day, and customers were already lining up for scheduled appointments. Our team at Belerick Garage Doors LLC arrived within the hour, thoroughly assessed the situation, and discovered both a broken torsion spring and a jammed track. Thanks to our rapid response and expert commercial garage door repair, we restored full function to the door system before lunch, ensuring the business avoided unnecessary downtime and lost revenue.

Situations like this happen more often than many people realize. According to data published by the Door and Access Systems Manufacturers Association (DASMA), over seventy percent of commercial garage door issues are linked directly to long-term wear and tear from daily use. In towns such as Brushy Creek, Texas, where commercial businesses rely on uninterrupted access and reliable security, a malfunctioning garage door can disrupt operations, reduce productivity, and create safety concerns for employees and customers alike.

This is precisely why it is so important for local business owners to recognize early signs of common commercial garage door problems and understand when to seek professional garage door repair services. In this comprehensive guide provided by Belerick Garage Doors LLC, a trusted name in garage door repair and maintenance, we will explore the most frequent commercial garage door issues that occur in the Brushy Creek area. By learning what to watch for and how to respond effectively, you can save your business time, reduce repair costs, and ensure your garage door system continues to function with precision and reliability.

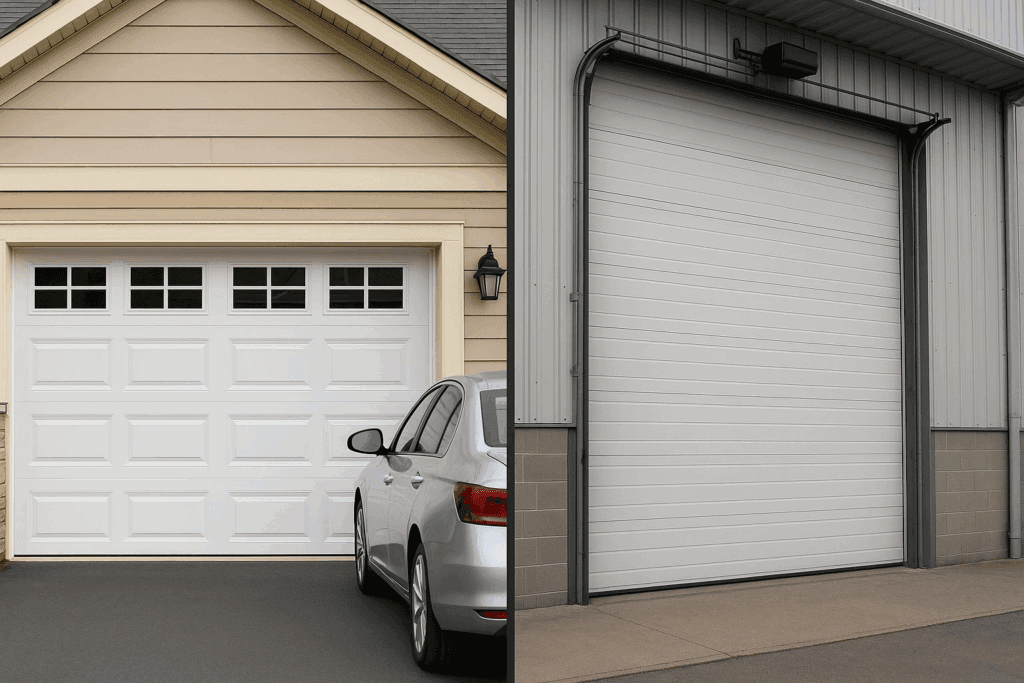

Why Commercial Garage Doors Differ from Residential Garage Doors

Commercial garage doors are specifically engineered to endure heavy use, provide enhanced security, and accommodate larger spaces. Unlike residential garage doors that typically open just a few times per day, commercial garage doors in Brushy Creek often operate dozens or even hundreds of times during a single workday, especially in industries such as shipping, automotive repair, storage facilities, and distribution centers.

These types of garage doors are commonly built using durable materials like steel or aluminum and are supported by advanced mechanical systems, including high-cycle torsion springs, heavy-duty rollers, reinforced tracks, and automated openers designed for frequent and reliable use. Because of these complex systems and demanding usage, commercial garage doors are more vulnerable to certain types of wear and mechanical stress than residential garage doors.

Additionally, commercial systems often require integration with other infrastructure such as security cameras, alarm systems, and remote monitoring software. This means that even a small problem with a commercial garage door can disrupt several other parts of your business operations. As such, the level of maintenance, inspection, and repair knowledge required is higher and should always be handled by certified professionals.

Understanding the key differences between commercial and residential garage door systems empowers business owners to make informed decisions about their maintenance schedules, repair needs, and overall investment in door security and performance. The better you understand the demands of your garage door system, the better prepared you are to address issues quickly and efficiently.

Worn or Broken Springs

One of the most frequent causes of commercial garage door failure is worn or broken springs. Springs play a crucial role in supporting the weight of the garage door, allowing it to open and close with controlled force. In commercial settings, torsion springs are typically used because they are stronger and more durable. However, even high-cycle springs have a limited lifespan, often measured in cycles rather than years.

For example, a standard commercial torsion spring may be rated for around 25,000 to 50,000 cycles. If your door operates 50 times per day, that spring may last only two to three years. When a spring fails, the door may become difficult to lift, get stuck midway, or stop functioning altogether. A loud snapping sound or sudden drop in the door’s movement can indicate a broken spring. Attempting to operate the door in this condition can result in further mechanical damage or pose a serious safety risk to personnel.

Warning signs of failing springs include:

- An unusually heavy door

- Gaps in the spring coils

- Loud popping noises during movement

- Inconsistent opening and closing

It is critical to contact a certified technician immediately if you suspect spring failure. At Belerick Garage Doors LLC, we replace worn springs with commercial-grade, high-cycle models specifically suited to your door size and usage needs, ensuring reliable performance and improved safety.

Misaligned or Damaged Tracks

Tracks are the guiding framework that allows your garage door to move vertically and horizontally during operation. In busy commercial environments, tracks can become damaged from accidental impacts, gradual wear, or poor maintenance. Misaligned tracks can cause the door to drag, become off-balance, or jam during movement.

Commercial tracks are often bolted directly to concrete or steel structures and must remain perfectly level and parallel for optimal performance. If a truck bumps the side rail or a forklift grazes the lower guide rail, the resulting misalignment can lead to immediate issues or gradual degradation. Misaligned tracks can also place strain on rollers, hinges, and the opener, reducing the efficiency and safety of the entire system.

Common signs of track problems include:

- Uneven door movement

- Grinding or scraping noises

- Door visibly leaning to one side

- Resistance during operation

At Belerick Garage Doors LLC, our technicians conduct detailed inspections using precision measurement tools. We realign tracks, replace damaged brackets, and secure mounting hardware to ensure smooth and quiet operation. Regular inspections of tracks can prevent long-term structural problems and improve the reliability of your door system.

Roller and Hinge Wear

Rollers and hinges are essential components that allow smooth and controlled garage door motion. In high-use environments, these parts undergo significant wear and can become noisy, loose, or inefficient over time. Most rollers are either nylon or steel, and each has a specific use case based on weight, door type, and operational frequency.

Worn rollers often result in:

- Jerky or bumpy door movement

- Loud screeching or grinding sounds

- Delays or resistance when opening or closing

If hinges begin to fail, you might notice the door sagging or flexing at connection points between panels. This can lead to uneven stress on other parts of the system, eventually causing chain reactions of wear and mechanical failure. Moisture, dust, and debris can also accelerate deterioration in Brushy Creek’s varying weather conditions.

At Belerick Garage Doors LLC, we recommend upgrading to sealed ball-bearing rollers for longer-lasting performance. Our expert technicians inspect all moving joints, replace worn components, and lubricate all pivot points using professional-grade products.

Opener and Motor Malfunctions

Garage door openers are the heart of automatic garage door systems. These motorized units control the lifting and lowering of the door and are heavily relied upon in commercial settings. Unfortunately, motor burnout, worn gears, faulty wiring, and system overloads are all common problems.

Business owners might experience:

- The door is not responding to remote or keypad commands

- Erratic or delayed motion

- Grinding or humming sounds without movement

- Flickering control panels or intermittent power

Modern openers include a variety of advanced features such as automatic diagnostics, rolling code security, and remote monitoring. If these features stop working, it may signal deeper electrical or software issues. Upgrading to a new model with smart technology can help streamline operations, especially for businesses managing multiple doors.

At Belerick Garage Doors LLC, our team has deep expertise with all major opener brands, including LiftMaster, Genie, and Chamberlain commercial models. We perform opener diagnostics, motor rewiring, logic board replacement, and full system upgrades tailored to your facility’s unique access needs.

Faulty Sensors and Safety Features

Safety sensors are an essential feature of any commercial garage door system. These sensors help detect obstructions in the path of the door, preventing accidents and injuries. Sensors must be properly aligned and free of debris to work correctly.

Sensor problems can result in:

- Doors reversing unexpectedly

- Doors refusing to close

- Intermittent function or failure to respond

Commercial codes in Brushy Creek often require functional photo-eye sensors and tested auto-reverse features as part of regulatory compliance. Accidents involving commercial doors can lead to lawsuits, fines, and serious injuries.

We recommend testing sensors monthly by placing a soft object like a roll of paper towels in the door’s path and observing whether it stops or reverses properly. Our team checks wiring connections, cleans lenses, and recalibrates sensors to ensure full compliance with safety standards.

Damaged or Dented Panels

Commercial garage doors are typically made of heavy-duty steel or aluminum panels, which are designed to withstand daily wear and exposure to the elements. However, accidental collisions with vehicles, weather-related damage such as hail or high winds, and general aging can all cause dents, warping, or cracks in these panels.

Even seemingly minor panel damage can have major consequences. A dent in a lower panel, for example, can throw off the door’s balance, leading to uneven movement and stress on the tracks and rollers. Cracks or separation in panels can also compromise the door’s insulation and energy efficiency, especially during Brushy Creek’s extreme summer heat or winter chills.

Instead of replacing the entire system, Belerick Garage Doors LLC offers targeted panel replacement services. We can match replacement panels to your existing door design and finish, preserving the visual appeal of your business frontage while restoring structural integrity. For property managers and building owners, this cost-effective approach can extend the useful life of a door system while maintaining compliance with safety standards.

Weather Stripping and Insulation Problems

Weather seals and insulation are critical elements in maintaining temperature control and protecting commercial interiors from outside elements. In Brushy Creek, commercial properties must account for wind, rain, dust, insects, and rapid temperature fluctuations. Poor sealing not only invites environmental hazards but can also significantly increase your building’s energy consumption.

Signs of failing weather stripping include:

- Visible gaps between the door and frame

- Moisture or debris on the interior floor

- Higher than usual heating or cooling costs

Insulation plays a major role in reducing thermal transfer and keeping indoor environments comfortable for employees, clients, and temperature-sensitive goods. Older doors with outdated or compressed insulation may struggle to maintain energy efficiency.

At Belerick Garage Doors LLC, we replace worn weather seals using commercial-grade rubber and vinyl materials. We also offer insulation upgrades for door panels, including polyurethane foam, polystyrene cores, and reflective foil barriers. These enhancements not only improve comfort but also help reduce the strain on HVAC systems, lowering operational costs over time.

Corrosion and Rust Buildup

Rust and corrosion are persistent threats to metal garage door systems, especially in regions with high humidity or exposure to industrial pollutants. In Brushy Creek, where temperature shifts and seasonal rains are common, untreated metal surfaces are especially vulnerable.

When corrosion sets in, it begins to weaken panels, hinges, bolts, and track hardware. Over time, rust can spread and lead to structural failure, particularly in load-bearing components such as support brackets and spring anchors.

Preventative care involves regularly inspecting vulnerable areas and applying protective coatings. Galvanized or powder-coated hardware offers better resistance, and stainless steel components can be used in high-moisture environments.

Our team at Belerick Garage Doors LLC performs rust mitigation treatments and replacement of corroded parts. We also advise on best practices for moisture control, such as improved drainage systems around garage entrances and the use of rust-inhibiting lubricants during maintenance.

Access Control and Keypad Failures

Modern commercial garage doors often incorporate remote access systems, wall-mounted keypads, proximity sensors, or app-based control platforms. These systems streamline daily operations, especially in facilities where multiple team members require timed or restricted access to loading areas.

However, issues can arise with aging hardware, poor signal transmission, or firmware glitches. If access systems fail, it can delay operations, reduce employee productivity, and increase security risks.

Common problems include:

- Dead keypad batteries or corroded terminals

- Remote programming errors

- Interference from nearby wireless devices

To mitigate these issues, we provide expert diagnosis and repair for all major access control systems. We also offer upgrades to newer technologies that include biometric access, encrypted communication, and remote audit logs that enhance building security and operational transparency.

Power Supply and Manual Override Issues

Commercial garage doors depend on consistent power to operate smoothly. When power is lost due to grid failure, internal electrical issues, or overloaded circuits, the system must include a reliable manual override or battery backup feature.

Unfortunately, these emergency mechanisms are often overlooked in maintenance routines. A stuck manual release handle or depleted battery backup can leave staff locked in or out of critical workspaces.

Belerick Garage Doors LLC includes testing of manual release systems and battery backups as part of our regular maintenance service. We ensure that your team has safe access to door functions in the event of a power outage, helping you maintain business continuity even during local electrical disruptions.

Unusual Reversing or Intermittent Movement

One of the most frustrating problems business owners face is when a commercial garage door starts to close, then reverses without cause, or behaves erratically during movement. This behavior can be dangerous, especially in busy warehouses or service bays.

Causes of this behavior include:

- Incorrect sensitivity settings on the opener

- Obstructed or dirty tracks

- Faulty sensors or frayed wires

- Tension imbalances in the spring system

These issues require professional calibration and mechanical adjustment. Our certified master technicians at Belerick Garage Doors LLC use diagnostic tools to pinpoint the exact cause and make targeted repairs. This results in smoother operation, improved safety, and fewer interruptions for your business.

Why Preventive Maintenance Is Essential

Preventative maintenance is more than just an optional service—it is a critical strategy for keeping your commercial garage door system functioning efficiently and safely. Commercial door systems involve many high-tension, moving components that experience stress every day. Without routine checks, small issues can develop into expensive breakdowns.

Benefits of preventative maintenance include:

- Extended equipment lifespan

- Reduced risk of emergency repairs

- Improved workplace safety

- Compliance with local and national safety standards

Our preventative maintenance services include a detailed inspection checklist that covers:

- Spring tension and wear

- Track alignment and cleanliness

- Opener performance and motor diagnostics

- Lubrication of rollers, hinges, and bearings

- Weather stripping integrity

- Sensor alignment and electrical testing

We recommend that high-traffic businesses schedule quarterly maintenance, while low-to-moderate use facilities may benefit from biannual inspections. Our team will tailor a schedule to match your specific needs, ensuring year-round performance and peace of mind.

How Can Belerick Garage Doors LLC Inc. Help You?

Belerick Garage Doors LLC proudly serves the Brushy Creek and Austin area with trusted commercial garage door repair, maintenance, and installation services. Our experienced technicians handle everything from minor part replacements to complex system overhauls with professionalism and efficiency.

We offer:

- Rapid emergency service

- Precision diagnostics and root cause analysis

- Spring, track, and opener repairs

- Commercial door installation and remodeling upgrades

- Access control system installation

- Flexible maintenance plans

Our goal is to be your one-stop shop for all garage door needs, from malfunctioning garage doors and fire doors to automatic doors and overhead door repair. Our technicians are fully trained and certified to work on a wide range of door systems and ensure every job is completed with top-quality service and parts.

When your business depends on reliable door systems, you need a team that delivers top quality and responsive service every time. Our one-stop shop approach ensures your commercial doors operate safely, securely, and efficiently.

Call Belerick Garage Doors LLC today at (512) 601-4514 or visit us on 701 Tillery St., Austin, TX 78702. Let us protect your business with dependable garage door service that meets all your commercial needs.

Final Thoughts

Commercial garage doors are a critical part of your business infrastructure. When they fail, your operations, safety, and security are all at risk. By understanding common issues like worn springs, misaligned tracks, malfunctioning openers, and damaged panels, you can take proactive steps to prevent breakdowns and ensure continuous function.

Brushy Creek businesses face a variety of operational and environmental challenges, and your garage door systems must be prepared to withstand those pressures. Partnering with a professional garage door service provider like Belerick Garage Doors LLC means you have access to expert technicians, fast repairs, and top-quality maintenance. Our team understands the unique demands of Brushy Creek businesses and delivers services that support your daily operations and long-term success.

Whether you are experiencing an emergency or planning regular maintenance, do not wait. Contact us today and let Belerick Garage Doors LLC become your trusted partner in commercial garage door care and reliability. We are committed to helping your business thrive with smooth, safe, and secure garage door systems you can depend on every day.

Frequently Asked Questions (FAQs)

1. How do I know if my commercial garage door needs a full replacement instead of just repairs?

If your garage door system is over 15 years old, frequently breaks down, or shows signs of major structural damage, it might be more cost-effective to replace it entirely. A professional inspection can determine whether repairs are safe or if a new installation will provide better long-term value.

2. Are there specific commercial garage door options designed for extreme weather conditions?

Yes, there are commercial doors built with reinforced panels, wind-load certifications, and insulated cores to withstand extreme temperatures and storms. These are ideal for areas like Brushy Creek that experience sudden weather changes.

3. Can I automate my existing commercial garage door with a smart opener system?

In many cases, yes. Most commercial garage doors can be retrofitted with modern opener systems that include smart access, app control, and remote diagnostics, as long as the existing structure is compatible.

4. What safety certifications should I look for in a commercial garage door service provider?

Look for technicians who are certified by the IDEA (Institute of Door Dealer Education and Accreditation) or have manufacturer-specific training. These certifications ensure the provider follows industry safety and installation standards.